Trebor® manufactures quartz heaters for deionized water and chemical applications, in addition to high purity, air operated double diaphragm (A.O.D.D) pumps for chemical applications. Our products can be used in multiple industries that require purity, process control, high temperatures, and small footprints.

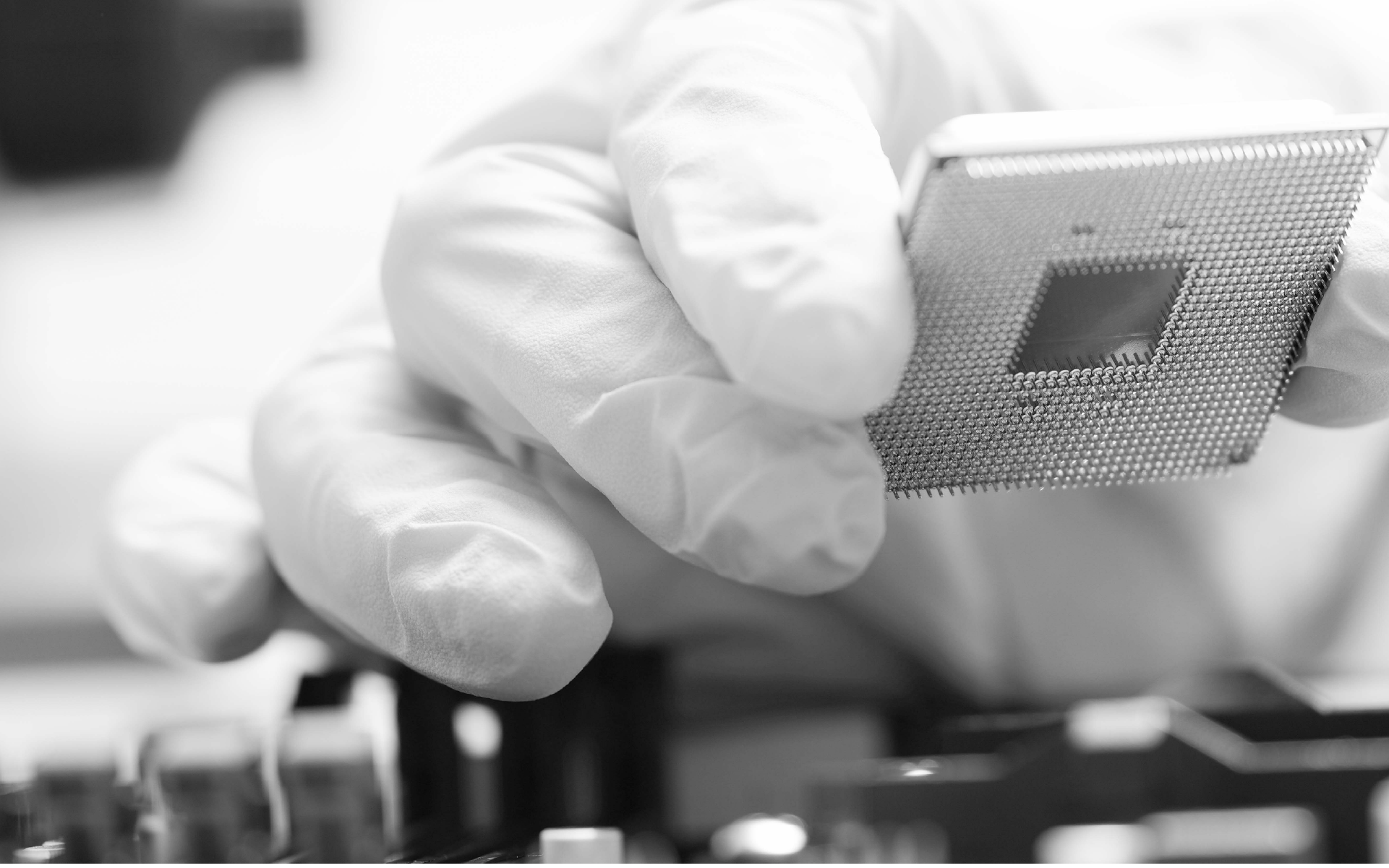

Heaters

Our heaters are designed to quickly heat fluids in a single pass with no metal components in the fluid path. We offer two types of heaters; inline chemical heaters and deionized water heaters. Our inline chemical heaters are popular because of their modular capabilities, size, and heating efficiency. These heaters have some unique design features that prevent bacteria growth, still water, or particle traps and therefore increase the yield of your process.

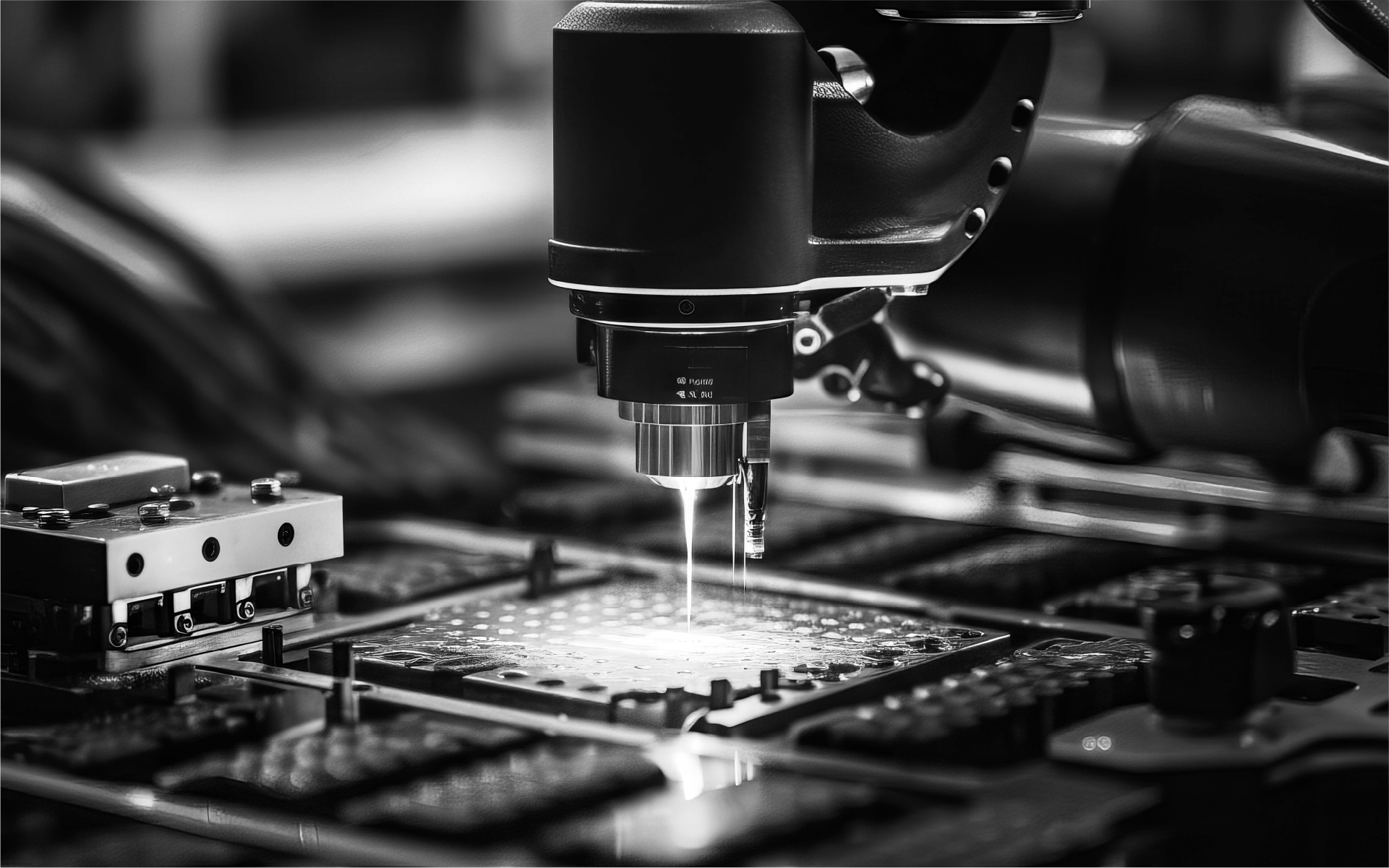

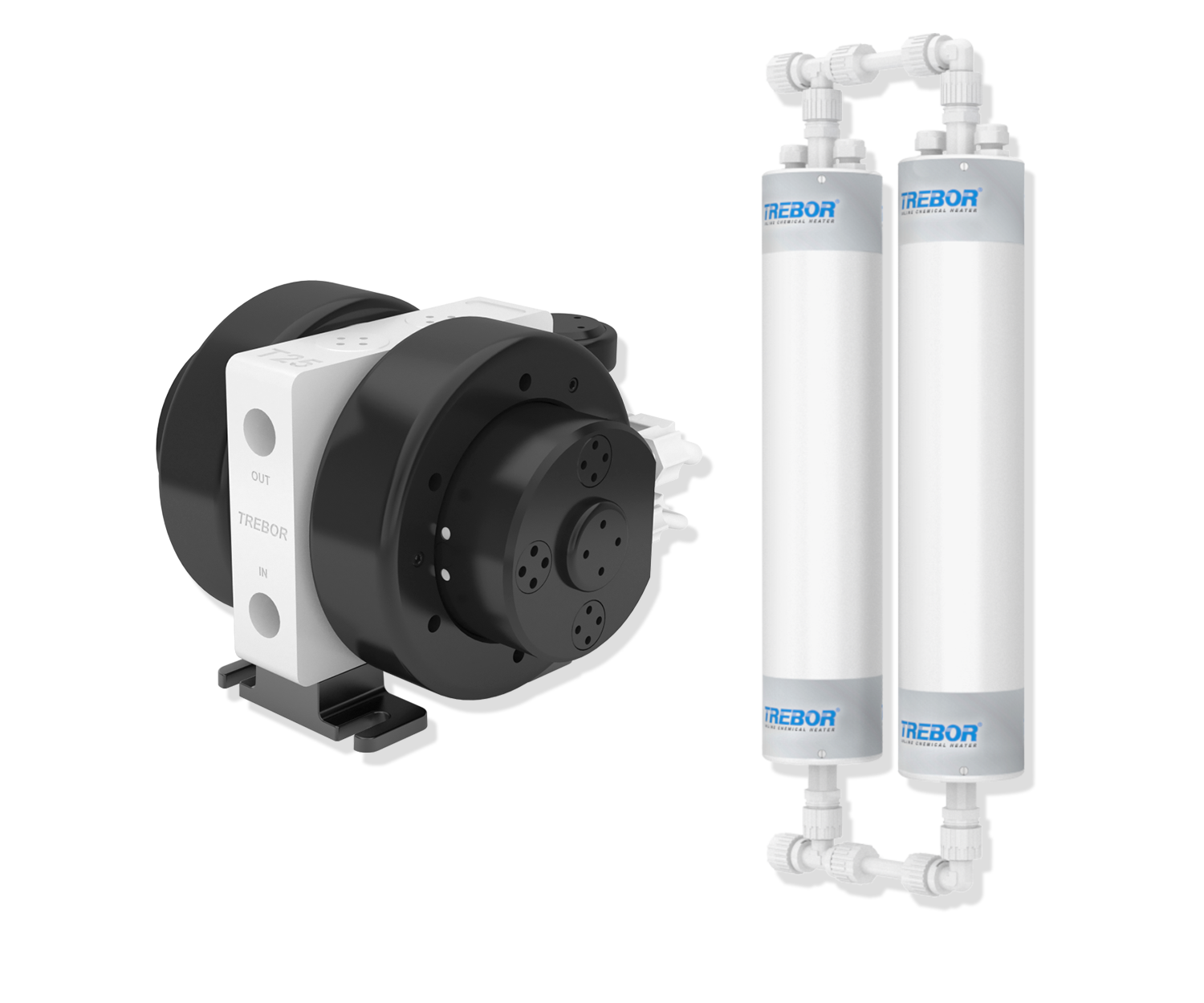

Pumps

Our pumps are designed for continuous operation in aggressive and process critical applications. That includes processes with the most aggressive chemical mixtures known in the industry. We use 100% virgin plastic resins, such as PTFE, PFA, and PP, because we know that maintaining purity is a critical element in your process.

Accessories

Our probes and monitoring systems provide complete performance and diagnostic capability for your high purity pump. The use of fiber optic technology allowed us to design a nonmetallic sensor that will not corrode in aggressive acid environments and avoid the use of electrical terminations that may create explosion risk in volatile solvent applications. All probes are nonintrusive so they will not adversely affect pump performance or come in contact with your ultrapure fluids during normal operation.