15

Jan

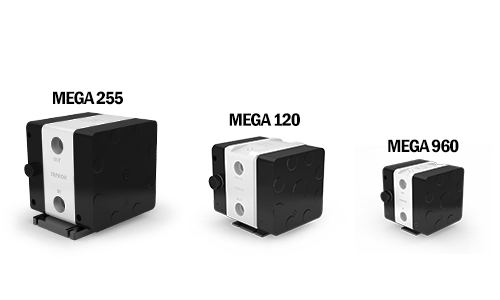

Mega Family Pumps

in Latest Posts

Comments

Since its introduction to the market in 1996, our Mega 960 “style” has been a vital pump used in the semiconductor, solar, and LED industries. Our Mega pump family offers a myriad of attributes that made it a key staple in the transferring, delivery and recirculation of chemistries. Here’s just a few reason why the Mega pumps are ideal for your application needs.

- Material – Made from virgin PTFE and PFA, the Mega Pump is capable of handling and delivering a variety of chemistries (click here to see our chemical resistance chart).

- No Metallic Risk – In the production of micro-electronics, metallic contamination can substantially reduce yield. That’s why the Mega pump was designed with no metallics in the fluid path. By eliminating the risk of ionic contamination, the Mega pump provides peace of mind to our customers.

- Built to Last – Each pump is designed with easy-to-replace frictional wear components like bore, shaft and check components. The body should never require replacement under normal operating conditions. If you’re interested in a low cost of ownership the Mega 960 provides the longest mean time between failure (MTBF) and lowest cost to repair out of any pneumatic pump in the chemical delivery market.

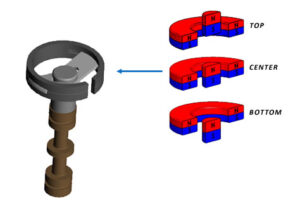

- Magnetic Shuttle – If you’re looking for innovation and enhanced performance you’ve found it! As of spring 2020, our Mega pumps offer a magnetic shuttle option. By utilizing the natural power of magnets, shuttle stalling is not a concern. Furthermore, the magnetic detent reduces the wearable components on the shuttle and lowers the cost of maintenance.

- Intelligent Pneumatic Distribution Technology – Our Mega pumps utilize smart pilots which tracks the position of the diaphragms at all time. These technologies are ideal for pumping against high system resistance/backpressure and are comfortable with dead-head conditions. Distribution technologies from Trebor are best utilized in direct dispense applications which eliminate the need for pressure vessels and return loops.

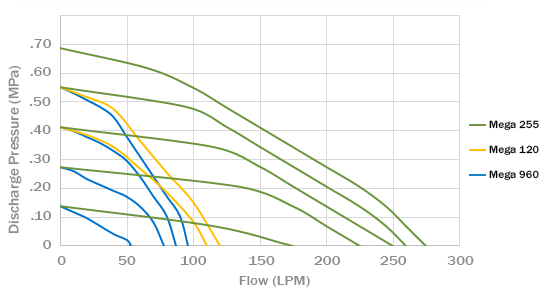

- Flow That Shows – Compare the difference flow rates of our Mega family pumps. If your application needs 50 to 255+ LPM, know that our Mega pumps has you covered.

Depending on your application, sometimes you need to speak with an expert for additional advice. CLICK HERE to contact our application specialist.