Mega 960

LnRiLWdyaWQsLnRiLWdyaWQ+LmJsb2NrLWVkaXRvci1pbm5lci1ibG9ja3M+LmJsb2NrLWVkaXRvci1ibG9jay1saXN0X19sYXlvdXR7ZGlzcGxheTpncmlkO2dyaWQtcm93LWdhcDoyNXB4O2dyaWQtY29sdW1uLWdhcDoyNXB4fS50Yi1ncmlkLWl0ZW17YmFja2dyb3VuZDojZDM4YTAzO3BhZGRpbmc6MzBweH0udGItZ3JpZC1jb2x1bW57ZmxleC13cmFwOndyYXB9LnRiLWdyaWQtY29sdW1uPip7d2lkdGg6MTAwJX0udGItZ3JpZC1jb2x1bW4udGItZ3JpZC1hbGlnbi10b3B7d2lkdGg6MTAwJTtkaXNwbGF5OmZsZXg7YWxpZ24tY29udGVudDpmbGV4LXN0YXJ0fS50Yi1ncmlkLWNvbHVtbi50Yi1ncmlkLWFsaWduLWNlbnRlcnt3aWR0aDoxMDAlO2Rpc3BsYXk6ZmxleDthbGlnbi1jb250ZW50OmNlbnRlcn0udGItZ3JpZC1jb2x1bW4udGItZ3JpZC1hbGlnbi1ib3R0b217d2lkdGg6MTAwJTtkaXNwbGF5OmZsZXg7YWxpZ24tY29udGVudDpmbGV4LWVuZH0gLndwLWJsb2NrLXRvb2xzZXQtYmxvY2tzLWdyaWQudGItZ3JpZFtkYXRhLXRvb2xzZXQtYmxvY2tzLWdyaWQ9ImZkNTVhNGRiMjE0NWVkNGUwYTA2MWQyMzg3MjAwOWEyIl0geyBncmlkLXRlbXBsYXRlLWNvbHVtbnM6IG1pbm1heCgwLCAwLjUxZnIpIG1pbm1heCgwLCAwLjQ5ZnIpO2dyaWQtYXV0by1mbG93OiByb3cgfSAud3AtYmxvY2stdG9vbHNldC1ibG9ja3MtZ3JpZC50Yi1ncmlkW2RhdGEtdG9vbHNldC1ibG9ja3MtZ3JpZD0iZmQ1NWE0ZGIyMTQ1ZWQ0ZTBhMDYxZDIzODcyMDA5YTIiXSA+IC50Yi1ncmlkLWNvbHVtbjpudGgtb2YtdHlwZSgybiArIDEpIHsgZ3JpZC1jb2x1bW46IDEgfSAud3AtYmxvY2stdG9vbHNldC1ibG9ja3MtZ3JpZC50Yi1ncmlkW2RhdGEtdG9vbHNldC1ibG9ja3MtZ3JpZD0iZmQ1NWE0ZGIyMTQ1ZWQ0ZTBhMDYxZDIzODcyMDA5YTIiXSA+IC50Yi1ncmlkLWNvbHVtbjpudGgtb2YtdHlwZSgybiArIDIpIHsgZ3JpZC1jb2x1bW46IDIgfSAudGItYnV0dG9ue2NvbG9yOiNmMWYxZjF9LnRiLWJ1dHRvbi0tbGVmdHt0ZXh0LWFsaWduOmxlZnR9LnRiLWJ1dHRvbi0tY2VudGVye3RleHQtYWxpZ246Y2VudGVyfS50Yi1idXR0b24tLXJpZ2h0e3RleHQtYWxpZ246cmlnaHR9LnRiLWJ1dHRvbl9fbGlua3tjb2xvcjppbmhlcml0O2N1cnNvcjpwb2ludGVyO2Rpc3BsYXk6aW5saW5lLWJsb2NrO2xpbmUtaGVpZ2h0OjEwMCU7dGV4dC1kZWNvcmF0aW9uOm5vbmUgIWltcG9ydGFudDt0ZXh0LWFsaWduOmNlbnRlcjt0cmFuc2l0aW9uOmFsbCAwLjNzIGVhc2V9LnRiLWJ1dHRvbl9fbGluazpob3ZlciwudGItYnV0dG9uX19saW5rOmZvY3VzLC50Yi1idXR0b25fX2xpbms6dmlzaXRlZHtjb2xvcjppbmhlcml0fS50Yi1idXR0b25fX2xpbms6aG92ZXIgLnRiLWJ1dHRvbl9fY29udGVudCwudGItYnV0dG9uX19saW5rOmZvY3VzIC50Yi1idXR0b25fX2NvbnRlbnQsLnRiLWJ1dHRvbl9fbGluazp2aXNpdGVkIC50Yi1idXR0b25fX2NvbnRlbnR7Zm9udC1mYW1pbHk6aW5oZXJpdDtmb250LXN0eWxlOmluaGVyaXQ7Zm9udC13ZWlnaHQ6aW5oZXJpdDtsZXR0ZXItc3BhY2luZzppbmhlcml0O3RleHQtZGVjb3JhdGlvbjppbmhlcml0O3RleHQtc2hhZG93OmluaGVyaXQ7dGV4dC10cmFuc2Zvcm06aW5oZXJpdH0udGItYnV0dG9uX19jb250ZW50e3ZlcnRpY2FsLWFsaWduOm1pZGRsZTt0cmFuc2l0aW9uOmFsbCAwLjNzIGVhc2V9LnRiLWJ1dHRvbl9faWNvbnt0cmFuc2l0aW9uOmFsbCAwLjNzIGVhc2U7ZGlzcGxheTppbmxpbmUtYmxvY2s7dmVydGljYWwtYWxpZ246bWlkZGxlO2ZvbnQtc3R5bGU6bm9ybWFsICFpbXBvcnRhbnR9LnRiLWJ1dHRvbl9faWNvbjo6YmVmb3Jle2NvbnRlbnQ6YXR0cihkYXRhLWZvbnQtY29kZSk7Zm9udC13ZWlnaHQ6bm9ybWFsICFpbXBvcnRhbnR9LnRiLWJ1dHRvbl9fbGlua3tiYWNrZ3JvdW5kLWNvbG9yOiM0NDQ7Ym9yZGVyLXJhZGl1czowLjNlbTtmb250LXNpemU6MS4zZW07bWFyZ2luLWJvdHRvbTowLjc2ZW07cGFkZGluZzowLjU1ZW0gMS41ZW0gMC41NWVtfSAudGItYnV0dG9uW2RhdGEtdG9vbHNldC1ibG9ja3MtYnV0dG9uPSI0MzY5OGM1Y2ExZGJjOWFkYjJkYzBmMzc2YzkzMDY3MSJdIC50Yi1idXR0b25fX2xpbmsgeyBiYWNrZ3JvdW5kLWNvbG9yOiByZ2JhKCAwLCAxMTUsIDIwNywgMSApO2JvcmRlci1yYWRpdXM6IDA7IH0gLnRiLWJ1dHRvbltkYXRhLXRvb2xzZXQtYmxvY2tzLWJ1dHRvbj0iNDM2OThjNWNhMWRiYzlhZGIyZGMwZjM3NmM5MzA2NzEiXSAudGItYnV0dG9uX19saW5rOmhvdmVyIHsgYmFja2dyb3VuZC1jb2xvcjogcmdiYSggMCwgMTE1LCAyMDksIDAuNzYgKTtib3JkZXItcmFkaXVzOiAwOyB9IC50Yi1idXR0b25bZGF0YS10b29sc2V0LWJsb2Nrcy1idXR0b249IjQzNjk4YzVjYTFkYmM5YWRiMmRjMGYzNzZjOTMwNjcxIl0gLnRiLWJ1dHRvbl9fbGluazphY3RpdmUgeyBib3JkZXItcmFkaXVzOiAwOyB9IC50Yi1idXR0b25bZGF0YS10b29sc2V0LWJsb2Nrcy1idXR0b249IjQzNjk4YzVjYTFkYmM5YWRiMmRjMGYzNzZjOTMwNjcxIl0gLnRiLWJ1dHRvbl9faWNvbiB7IGZvbnQtZmFtaWx5OiBkYXNoaWNvbnM7IH0gLndwLWJsb2NrLXRvb2xzZXQtYmxvY2tzLWdyaWQtY29sdW1uLnRiLWdyaWQtY29sdW1uW2RhdGEtdG9vbHNldC1ibG9ja3MtZ3JpZC1jb2x1bW49IjMwMzRmYmU4ODZjMTEwNTRlOTViNDZiMDlkM2U0MTEyIl0geyBkaXNwbGF5OiBmbGV4OyB9IC50Yi1pbWFnZS1zbGlkZXItLWNhcm91c2Vse29wYWNpdHk6MDtkaXJlY3Rpb246bHRyfS50Yi1pbWFnZS1zbGlkZXIgLmdsaWRle3Bvc2l0aW9uOnJlbGF0aXZlfS50Yi1pbWFnZS1zbGlkZXIgLmdsaWRlX19zbGlkZXtoZWlnaHQ6YXV0bztwb3NpdGlvbjpyZWxhdGl2ZTttYXJnaW4tbGVmdDowfS50Yi1pbWFnZS1zbGlkZXIgLmdsaWRlX19zbGlkZS0tY2xvbmV7Y3Vyc29yOnBvaW50ZXJ9LnRiLWltYWdlLXNsaWRlciAuZ2xpZGVfX3NsaWRlIGltZ3t3aWR0aDoxMDAlO2Zsb2F0Om5vbmUgIWltcG9ydGFudH0udGItaW1hZ2Utc2xpZGVyIC5nbGlkZV9fdmlld3t3aWR0aDoxMDAlO3RyYW5zaXRpb246b3BhY2l0eSAzNTBtcyBlYXNlLWluLW91dDtwb3NpdGlvbjpyZWxhdGl2ZX0udGItaW1hZ2Utc2xpZGVyIC5nbGlkZV9fdmlldyBpbWd7LW8tb2JqZWN0LWZpdDpjb250YWluO29iamVjdC1maXQ6Y29udGFpbjt3aWR0aDoxMDAlO2Zsb2F0Om5vbmUgIWltcG9ydGFudH0udGItaW1hZ2Utc2xpZGVyIC5nbGlkZV9fdmlldy0tZmFkZS1vdXR7b3BhY2l0eTowfS50Yi1pbWFnZS1zbGlkZXIgLmdsaWRlX192aWV3LS1mYWRlLWlue29wYWNpdHk6MX0udGItaW1hZ2Utc2xpZGVyIC5nbGlkZV9fYXJyb3d7Ym9yZGVyOm5vbmU7cG9zaXRpb246YWJzb2x1dGU7ei1pbmRleDoxMDt0b3A6NTAlO2Rpc3BsYXk6aW5saW5lLWZsZXg7anVzdGlmeS1jb250ZW50OmNlbnRlcjthbGlnbi1pdGVtczpjZW50ZXI7d2lkdGg6NDBweDtoZWlnaHQ6NDBweDt0ZXh0LWFsaWduOmNlbnRlcjtwYWRkaW5nOjA7Y3Vyc29yOnBvaW50ZXI7dHJhbnNmb3JtOnRyYW5zbGF0ZVkoLTUwJSk7Ym9yZGVyLXJhZGl1czo1MHB4O3RyYW5zaXRpb246YWxsIDAuMnMgbGluZWFyO2JhY2tncm91bmQ6cmdiYSgyNTUsMjU1LDI1NSwwLjcpfS50Yi1pbWFnZS1zbGlkZXIgLmdsaWRlX19hcnJvdzpmb2N1c3tvdXRsaW5lOm5vbmU7Ym94LXNoYWRvdzowIDAgNXB4ICM2NjY7YmFja2dyb3VuZDpyZ2JhKDI1NSwyNTUsMjU1LDAuNyk7b3BhY2l0eToxfS50Yi1pbWFnZS1zbGlkZXIgLmdsaWRlX19hcnJvdzpob3ZlcntiYWNrZ3JvdW5kOnJnYmEoMjU1LDI1NSwyNTUsMC45KX0udGItaW1hZ2Utc2xpZGVyIC5nbGlkZV9fYXJyb3ctLWxlZnR7bGVmdDo1cHh9LnRiLWltYWdlLXNsaWRlciAuZ2xpZGVfX2Fycm93LS1sZWZ0IHN2Z3ttYXJnaW4tbGVmdDotMXB4fS50Yi1pbWFnZS1zbGlkZXIgLmdsaWRlX19hcnJvdy0tbGVmdCBzcGFuLnRiLXNsaWRlci1sZWZ0LWFycm93e2Rpc3BsYXk6aW5saW5lLWJsb2NrO3dpZHRoOjI1cHg7aGVpZ2h0OjI1cHg7YmFja2dyb3VuZC1pbWFnZTp1cmwoImRhdGE6aW1hZ2Uvc3ZnK3htbCwlM0NzdmcgeG1sbnM9J2h0dHA6Ly93d3cudzMub3JnLzIwMDAvc3ZnJyB2aWV3Qm94PScwIDAgMTI5IDEyOScgd2lkdGg9JzI1JyBoZWlnaHQ9JzI1JyUzRSUzQ2clM0UlM0NwYXRoIGQ9J203MCw5My41YzAuOCwwLjggMS44LDEuMiAyLjksMS4yIDEsMCAyLjEtMC40IDIuOS0xLjIgMS42LTEuNiAxLjYtNC4yIDAtNS44bC0yMy41LTIzLjUgMjMuNS0yMy41YzEuNi0xLjYgMS42LTQuMiAwLTUuOHMtNC4yLTEuNi01LjgsMGwtMjYuNCwyNi40Yy0wLjgsMC44LTEuMiwxLjgtMS4yLDIuOXMwLjQsMi4xIDEuMiwyLjlsMjYuNCwyNi40eicgZmlsbD0nJTIzNjY2Jy8lM0UlM0MvZyUzRSUzQy9zdmclM0UiKX0udGItaW1hZ2Utc2xpZGVyIC5nbGlkZV9fYXJyb3ctLXJpZ2h0e3JpZ2h0OjVweH0udGItaW1hZ2Utc2xpZGVyIC5nbGlkZV9fYXJyb3ctLXJpZ2h0IHN2Z3ttYXJnaW4tcmlnaHQ6LTFweH0udGItaW1hZ2Utc2xpZGVyIC5nbGlkZV9fYXJyb3ctLXJpZ2h0IHNwYW4udGItc2xpZGVyLXJpZ2h0LWFycm93e2Rpc3BsYXk6aW5saW5lLWJsb2NrO3dpZHRoOjI1cHg7aGVpZ2h0OjI1cHg7YmFja2dyb3VuZC1pbWFnZTp1cmwoImRhdGE6aW1hZ2Uvc3ZnK3htbCwlM0NzdmcgeG1sbnM9J2h0dHA6Ly93d3cudzMub3JnLzIwMDAvc3ZnJyB2aWV3Qm94PScwIDAgMTI5IDEyOScgd2lkdGg9JzI1JyBoZWlnaHQ9JzI1JyUzRSUzQ2clM0UlM0NwYXRoIGQ9J201MS4xLDkzLjVjMC44LDAuOCAxLjgsMS4yIDIuOSwxLjIgMSwwIDIuMS0wLjQgMi45LTEuMmwyNi40LTI2LjRjMC44LTAuOCAxLjItMS44IDEuMi0yLjkgMC0xLjEtMC40LTIuMS0xLjItMi45bC0yNi40LTI2LjRjLTEuNi0xLjYtNC4yLTEuNi01LjgsMC0xLjYsMS42LTEuNiw0LjIgMCw1LjhsMjMuNSwyMy41LTIzLjUsMjMuNWMtMS42LDEuNi0xLjYsNC4yIDAsNS44eicgZmlsbD0nJTIzNjY2Jy8lM0UlM0MvZyUzRSUzQy9zdmclM0UiKX0udGItaW1hZ2Utc2xpZGVyIC5nbGlkZTpob3ZlciAuZ2xpZGVfX2Fycm93LC50Yi1pbWFnZS1zbGlkZXIgLmdsaWRlOmZvY3VzIC5nbGlkZV9fYXJyb3d7b3BhY2l0eToxfS50Yi1pbWFnZS1zbGlkZXItLWNyb3AgLmdsaWRlX19zbGlkZSBpbWd7LW8tb2JqZWN0LWZpdDpjb3ZlcjtvYmplY3QtZml0OmNvdmVyO2hlaWdodDoxMDAlICFpbXBvcnRhbnR9LnRiLWltYWdlLXNsaWRlciAuZ2xpZGVfX3NsaWRlc3tsaXN0LXN0eWxlLXR5cGU6bm9uZTtwYWRkaW5nLWxlZnQ6MDttYXJnaW4tbGVmdDphdXRvfS50Yi1pbWFnZS1zbGlkZXJfX2NhcHRpb257cG9zaXRpb246YWJzb2x1dGU7Ym90dG9tOjA7d2lkdGg6MTAwJTtiYWNrZ3JvdW5kOnJnYmEoMjU1LDI1NSwyNTUsMC42KTt0ZXh0LWFsaWduOmNlbnRlcjtjb2xvcjojMzMzfS50Yi1pbWFnZS1zbGlkZXJfX2NhcHRpb24gOmVtcHR5e2JhY2tncm91bmQ6dHJhbnNwYXJlbnQgIWltcG9ydGFudDttYXJnaW46MDtwYWRkaW5nOjB9LnRiLWltYWdlLXNsaWRlcl9fY2FwdGlvbiBmaWdjYXB0aW9ue3BhZGRpbmc6NXB4IDJweDttYXJnaW4tdG9wOjVweH1AbWVkaWEgb25seSBzY3JlZW4gYW5kIChtYXgtd2lkdGg6IDc4MXB4KSB7IC50Yi1ncmlkLC50Yi1ncmlkPi5ibG9jay1lZGl0b3ItaW5uZXItYmxvY2tzPi5ibG9jay1lZGl0b3ItYmxvY2stbGlzdF9fbGF5b3V0e2Rpc3BsYXk6Z3JpZDtncmlkLXJvdy1nYXA6MjVweDtncmlkLWNvbHVtbi1nYXA6MjVweH0udGItZ3JpZC1pdGVte2JhY2tncm91bmQ6I2QzOGEwMztwYWRkaW5nOjMwcHh9LnRiLWdyaWQtY29sdW1ue2ZsZXgtd3JhcDp3cmFwfS50Yi1ncmlkLWNvbHVtbj4qe3dpZHRoOjEwMCV9LnRiLWdyaWQtY29sdW1uLnRiLWdyaWQtYWxpZ24tdG9we3dpZHRoOjEwMCU7ZGlzcGxheTpmbGV4O2FsaWduLWNvbnRlbnQ6ZmxleC1zdGFydH0udGItZ3JpZC1jb2x1bW4udGItZ3JpZC1hbGlnbi1jZW50ZXJ7d2lkdGg6MTAwJTtkaXNwbGF5OmZsZXg7YWxpZ24tY29udGVudDpjZW50ZXJ9LnRiLWdyaWQtY29sdW1uLnRiLWdyaWQtYWxpZ24tYm90dG9te3dpZHRoOjEwMCU7ZGlzcGxheTpmbGV4O2FsaWduLWNvbnRlbnQ6ZmxleC1lbmR9IC53cC1ibG9jay10b29sc2V0LWJsb2Nrcy1ncmlkLnRiLWdyaWRbZGF0YS10b29sc2V0LWJsb2Nrcy1ncmlkPSJmZDU1YTRkYjIxNDVlZDRlMGEwNjFkMjM4NzIwMDlhMiJdIHsgZ3JpZC10ZW1wbGF0ZS1jb2x1bW5zOiBtaW5tYXgoMCwgMC41ZnIpIG1pbm1heCgwLCAwLjVmcik7Z3JpZC1hdXRvLWZsb3c6IHJvdyB9IC53cC1ibG9jay10b29sc2V0LWJsb2Nrcy1ncmlkLnRiLWdyaWRbZGF0YS10b29sc2V0LWJsb2Nrcy1ncmlkPSJmZDU1YTRkYjIxNDVlZDRlMGEwNjFkMjM4NzIwMDlhMiJdID4gLnRiLWdyaWQtY29sdW1uOm50aC1vZi10eXBlKDJuICsgMSkgeyBncmlkLWNvbHVtbjogMSB9IC53cC1ibG9jay10b29sc2V0LWJsb2Nrcy1ncmlkLnRiLWdyaWRbZGF0YS10b29sc2V0LWJsb2Nrcy1ncmlkPSJmZDU1YTRkYjIxNDVlZDRlMGEwNjFkMjM4NzIwMDlhMiJdID4gLnRiLWdyaWQtY29sdW1uOm50aC1vZi10eXBlKDJuICsgMikgeyBncmlkLWNvbHVtbjogMiB9IC50Yi1idXR0b257Y29sb3I6I2YxZjFmMX0udGItYnV0dG9uLS1sZWZ0e3RleHQtYWxpZ246bGVmdH0udGItYnV0dG9uLS1jZW50ZXJ7dGV4dC1hbGlnbjpjZW50ZXJ9LnRiLWJ1dHRvbi0tcmlnaHR7dGV4dC1hbGlnbjpyaWdodH0udGItYnV0dG9uX19saW5re2NvbG9yOmluaGVyaXQ7Y3Vyc29yOnBvaW50ZXI7ZGlzcGxheTppbmxpbmUtYmxvY2s7bGluZS1oZWlnaHQ6MTAwJTt0ZXh0LWRlY29yYXRpb246bm9uZSAhaW1wb3J0YW50O3RleHQtYWxpZ246Y2VudGVyO3RyYW5zaXRpb246YWxsIDAuM3MgZWFzZX0udGItYnV0dG9uX19saW5rOmhvdmVyLC50Yi1idXR0b25fX2xpbms6Zm9jdXMsLnRiLWJ1dHRvbl9fbGluazp2aXNpdGVke2NvbG9yOmluaGVyaXR9LnRiLWJ1dHRvbl9fbGluazpob3ZlciAudGItYnV0dG9uX19jb250ZW50LC50Yi1idXR0b25fX2xpbms6Zm9jdXMgLnRiLWJ1dHRvbl9fY29udGVudCwudGItYnV0dG9uX19saW5rOnZpc2l0ZWQgLnRiLWJ1dHRvbl9fY29udGVudHtmb250LWZhbWlseTppbmhlcml0O2ZvbnQtc3R5bGU6aW5oZXJpdDtmb250LXdlaWdodDppbmhlcml0O2xldHRlci1zcGFjaW5nOmluaGVyaXQ7dGV4dC1kZWNvcmF0aW9uOmluaGVyaXQ7dGV4dC1zaGFkb3c6aW5oZXJpdDt0ZXh0LXRyYW5zZm9ybTppbmhlcml0fS50Yi1idXR0b25fX2NvbnRlbnR7dmVydGljYWwtYWxpZ246bWlkZGxlO3RyYW5zaXRpb246YWxsIDAuM3MgZWFzZX0udGItYnV0dG9uX19pY29ue3RyYW5zaXRpb246YWxsIDAuM3MgZWFzZTtkaXNwbGF5OmlubGluZS1ibG9jazt2ZXJ0aWNhbC1hbGlnbjptaWRkbGU7Zm9udC1zdHlsZTpub3JtYWwgIWltcG9ydGFudH0udGItYnV0dG9uX19pY29uOjpiZWZvcmV7Y29udGVudDphdHRyKGRhdGEtZm9udC1jb2RlKTtmb250LXdlaWdodDpub3JtYWwgIWltcG9ydGFudH0udGItYnV0dG9uX19saW5re2JhY2tncm91bmQtY29sb3I6IzQ0NDtib3JkZXItcmFkaXVzOjAuM2VtO2ZvbnQtc2l6ZToxLjNlbTttYXJnaW4tYm90dG9tOjAuNzZlbTtwYWRkaW5nOjAuNTVlbSAxLjVlbSAwLjU1ZW19LndwLWJsb2NrLXRvb2xzZXQtYmxvY2tzLWdyaWQtY29sdW1uLnRiLWdyaWQtY29sdW1uW2RhdGEtdG9vbHNldC1ibG9ja3MtZ3JpZC1jb2x1bW49IjMwMzRmYmU4ODZjMTEwNTRlOTViNDZiMDlkM2U0MTEyIl0geyBkaXNwbGF5OiBmbGV4OyB9IC50Yi1pbWFnZS1zbGlkZXItLWNhcm91c2Vse29wYWNpdHk6MDtkaXJlY3Rpb246bHRyfS50Yi1pbWFnZS1zbGlkZXIgLmdsaWRle3Bvc2l0aW9uOnJlbGF0aXZlfS50Yi1pbWFnZS1zbGlkZXIgLmdsaWRlX19zbGlkZXtoZWlnaHQ6YXV0bztwb3NpdGlvbjpyZWxhdGl2ZTttYXJnaW4tbGVmdDowfS50Yi1pbWFnZS1zbGlkZXIgLmdsaWRlX19zbGlkZS0tY2xvbmV7Y3Vyc29yOnBvaW50ZXJ9LnRiLWltYWdlLXNsaWRlciAuZ2xpZGVfX3NsaWRlIGltZ3t3aWR0aDoxMDAlO2Zsb2F0Om5vbmUgIWltcG9ydGFudH0udGItaW1hZ2Utc2xpZGVyIC5nbGlkZV9fdmlld3t3aWR0aDoxMDAlO3RyYW5zaXRpb246b3BhY2l0eSAzNTBtcyBlYXNlLWluLW91dDtwb3NpdGlvbjpyZWxhdGl2ZX0udGItaW1hZ2Utc2xpZGVyIC5nbGlkZV9fdmlldyBpbWd7LW8tb2JqZWN0LWZpdDpjb250YWluO29iamVjdC1maXQ6Y29udGFpbjt3aWR0aDoxMDAlO2Zsb2F0Om5vbmUgIWltcG9ydGFudH0udGItaW1hZ2Utc2xpZGVyIC5nbGlkZV9fdmlldy0tZmFkZS1vdXR7b3BhY2l0eTowfS50Yi1pbWFnZS1zbGlkZXIgLmdsaWRlX192aWV3LS1mYWRlLWlue29wYWNpdHk6MX0udGItaW1hZ2Utc2xpZGVyIC5nbGlkZV9fYXJyb3d7Ym9yZGVyOm5vbmU7cG9zaXRpb246YWJzb2x1dGU7ei1pbmRleDoxMDt0b3A6NTAlO2Rpc3BsYXk6aW5saW5lLWZsZXg7anVzdGlmeS1jb250ZW50OmNlbnRlcjthbGlnbi1pdGVtczpjZW50ZXI7d2lkdGg6NDBweDtoZWlnaHQ6NDBweDt0ZXh0LWFsaWduOmNlbnRlcjtwYWRkaW5nOjA7Y3Vyc29yOnBvaW50ZXI7dHJhbnNmb3JtOnRyYW5zbGF0ZVkoLTUwJSk7Ym9yZGVyLXJhZGl1czo1MHB4O3RyYW5zaXRpb246YWxsIDAuMnMgbGluZWFyO2JhY2tncm91bmQ6cmdiYSgyNTUsMjU1LDI1NSwwLjcpfS50Yi1pbWFnZS1zbGlkZXIgLmdsaWRlX19hcnJvdzpmb2N1c3tvdXRsaW5lOm5vbmU7Ym94LXNoYWRvdzowIDAgNXB4ICM2NjY7YmFja2dyb3VuZDpyZ2JhKDI1NSwyNTUsMjU1LDAuNyk7b3BhY2l0eToxfS50Yi1pbWFnZS1zbGlkZXIgLmdsaWRlX19hcnJvdzpob3ZlcntiYWNrZ3JvdW5kOnJnYmEoMjU1LDI1NSwyNTUsMC45KX0udGItaW1hZ2Utc2xpZGVyIC5nbGlkZV9fYXJyb3ctLWxlZnR7bGVmdDo1cHh9LnRiLWltYWdlLXNsaWRlciAuZ2xpZGVfX2Fycm93LS1sZWZ0IHN2Z3ttYXJnaW4tbGVmdDotMXB4fS50Yi1pbWFnZS1zbGlkZXIgLmdsaWRlX19hcnJvdy0tbGVmdCBzcGFuLnRiLXNsaWRlci1sZWZ0LWFycm93e2Rpc3BsYXk6aW5saW5lLWJsb2NrO3dpZHRoOjI1cHg7aGVpZ2h0OjI1cHg7YmFja2dyb3VuZC1pbWFnZTp1cmwoImRhdGE6aW1hZ2Uvc3ZnK3htbCwlM0NzdmcgeG1sbnM9J2h0dHA6Ly93d3cudzMub3JnLzIwMDAvc3ZnJyB2aWV3Qm94PScwIDAgMTI5IDEyOScgd2lkdGg9JzI1JyBoZWlnaHQ9JzI1JyUzRSUzQ2clM0UlM0NwYXRoIGQ9J203MCw5My41YzAuOCwwLjggMS44LDEuMiAyLjksMS4yIDEsMCAyLjEtMC40IDIuOS0xLjIgMS42LTEuNiAxLjYtNC4yIDAtNS44bC0yMy41LTIzLjUgMjMuNS0yMy41YzEuNi0xLjYgMS42LTQuMiAwLTUuOHMtNC4yLTEuNi01LjgsMGwtMjYuNCwyNi40Yy0wLjgsMC44LTEuMiwxLjgtMS4yLDIuOXMwLjQsMi4xIDEuMiwyLjlsMjYuNCwyNi40eicgZmlsbD0nJTIzNjY2Jy8lM0UlM0MvZyUzRSUzQy9zdmclM0UiKX0udGItaW1hZ2Utc2xpZGVyIC5nbGlkZV9fYXJyb3ctLXJpZ2h0e3JpZ2h0OjVweH0udGItaW1hZ2Utc2xpZGVyIC5nbGlkZV9fYXJyb3ctLXJpZ2h0IHN2Z3ttYXJnaW4tcmlnaHQ6LTFweH0udGItaW1hZ2Utc2xpZGVyIC5nbGlkZV9fYXJyb3ctLXJpZ2h0IHNwYW4udGItc2xpZGVyLXJpZ2h0LWFycm93e2Rpc3BsYXk6aW5saW5lLWJsb2NrO3dpZHRoOjI1cHg7aGVpZ2h0OjI1cHg7YmFja2dyb3VuZC1pbWFnZTp1cmwoImRhdGE6aW1hZ2Uvc3ZnK3htbCwlM0NzdmcgeG1sbnM9J2h0dHA6Ly93d3cudzMub3JnLzIwMDAvc3ZnJyB2aWV3Qm94PScwIDAgMTI5IDEyOScgd2lkdGg9JzI1JyBoZWlnaHQ9JzI1JyUzRSUzQ2clM0UlM0NwYXRoIGQ9J201MS4xLDkzLjVjMC44LDAuOCAxLjgsMS4yIDIuOSwxLjIgMSwwIDIuMS0wLjQgMi45LTEuMmwyNi40LTI2LjRjMC44LTAuOCAxLjItMS44IDEuMi0yLjkgMC0xLjEtMC40LTIuMS0xLjItMi45bC0yNi40LTI2LjRjLTEuNi0xLjYtNC4yLTEuNi01LjgsMC0xLjYsMS42LTEuNiw0LjIgMCw1LjhsMjMuNSwyMy41LTIzLjUsMjMuNWMtMS42LDEuNi0xLjYsNC4yIDAsNS44eicgZmlsbD0nJTIzNjY2Jy8lM0UlM0MvZyUzRSUzQy9zdmclM0UiKX0udGItaW1hZ2Utc2xpZGVyIC5nbGlkZTpob3ZlciAuZ2xpZGVfX2Fycm93LC50Yi1pbWFnZS1zbGlkZXIgLmdsaWRlOmZvY3VzIC5nbGlkZV9fYXJyb3d7b3BhY2l0eToxfS50Yi1pbWFnZS1zbGlkZXItLWNyb3AgLmdsaWRlX19zbGlkZSBpbWd7LW8tb2JqZWN0LWZpdDpjb3ZlcjtvYmplY3QtZml0OmNvdmVyO2hlaWdodDoxMDAlICFpbXBvcnRhbnR9LnRiLWltYWdlLXNsaWRlciAuZ2xpZGVfX3NsaWRlc3tsaXN0LXN0eWxlLXR5cGU6bm9uZTtwYWRkaW5nLWxlZnQ6MDttYXJnaW4tbGVmdDphdXRvfS50Yi1pbWFnZS1zbGlkZXJfX2NhcHRpb257cG9zaXRpb246YWJzb2x1dGU7Ym90dG9tOjA7d2lkdGg6MTAwJTtiYWNrZ3JvdW5kOnJnYmEoMjU1LDI1NSwyNTUsMC42KTt0ZXh0LWFsaWduOmNlbnRlcjtjb2xvcjojMzMzfS50Yi1pbWFnZS1zbGlkZXJfX2NhcHRpb24gOmVtcHR5e2JhY2tncm91bmQ6dHJhbnNwYXJlbnQgIWltcG9ydGFudDttYXJnaW46MDtwYWRkaW5nOjB9LnRiLWltYWdlLXNsaWRlcl9fY2FwdGlvbiBmaWdjYXB0aW9ue3BhZGRpbmc6NXB4IDJweDttYXJnaW4tdG9wOjVweH0gfSBAbWVkaWEgb25seSBzY3JlZW4gYW5kIChtYXgtd2lkdGg6IDU5OXB4KSB7IC50Yi1ncmlkLC50Yi1ncmlkPi5ibG9jay1lZGl0b3ItaW5uZXItYmxvY2tzPi5ibG9jay1lZGl0b3ItYmxvY2stbGlzdF9fbGF5b3V0e2Rpc3BsYXk6Z3JpZDtncmlkLXJvdy1nYXA6MjVweDtncmlkLWNvbHVtbi1nYXA6MjVweH0udGItZ3JpZC1pdGVte2JhY2tncm91bmQ6I2QzOGEwMztwYWRkaW5nOjMwcHh9LnRiLWdyaWQtY29sdW1ue2ZsZXgtd3JhcDp3cmFwfS50Yi1ncmlkLWNvbHVtbj4qe3dpZHRoOjEwMCV9LnRiLWdyaWQtY29sdW1uLnRiLWdyaWQtYWxpZ24tdG9we3dpZHRoOjEwMCU7ZGlzcGxheTpmbGV4O2FsaWduLWNvbnRlbnQ6ZmxleC1zdGFydH0udGItZ3JpZC1jb2x1bW4udGItZ3JpZC1hbGlnbi1jZW50ZXJ7d2lkdGg6MTAwJTtkaXNwbGF5OmZsZXg7YWxpZ24tY29udGVudDpjZW50ZXJ9LnRiLWdyaWQtY29sdW1uLnRiLWdyaWQtYWxpZ24tYm90dG9te3dpZHRoOjEwMCU7ZGlzcGxheTpmbGV4O2FsaWduLWNvbnRlbnQ6ZmxleC1lbmR9IC53cC1ibG9jay10b29sc2V0LWJsb2Nrcy1ncmlkLnRiLWdyaWRbZGF0YS10b29sc2V0LWJsb2Nrcy1ncmlkPSJmZDU1YTRkYjIxNDVlZDRlMGEwNjFkMjM4NzIwMDlhMiJdIHsgZ3JpZC10ZW1wbGF0ZS1jb2x1bW5zOiBtaW5tYXgoMCwgMWZyKTtncmlkLWF1dG8tZmxvdzogcm93IH0gLndwLWJsb2NrLXRvb2xzZXQtYmxvY2tzLWdyaWQudGItZ3JpZFtkYXRhLXRvb2xzZXQtYmxvY2tzLWdyaWQ9ImZkNTVhNGRiMjE0NWVkNGUwYTA2MWQyMzg3MjAwOWEyIl0gID4gLnRiLWdyaWQtY29sdW1uOm50aC1vZi10eXBlKDFuKzEpIHsgZ3JpZC1jb2x1bW46IDEgfSAudGItYnV0dG9ue2NvbG9yOiNmMWYxZjF9LnRiLWJ1dHRvbi0tbGVmdHt0ZXh0LWFsaWduOmxlZnR9LnRiLWJ1dHRvbi0tY2VudGVye3RleHQtYWxpZ246Y2VudGVyfS50Yi1idXR0b24tLXJpZ2h0e3RleHQtYWxpZ246cmlnaHR9LnRiLWJ1dHRvbl9fbGlua3tjb2xvcjppbmhlcml0O2N1cnNvcjpwb2ludGVyO2Rpc3BsYXk6aW5saW5lLWJsb2NrO2xpbmUtaGVpZ2h0OjEwMCU7dGV4dC1kZWNvcmF0aW9uOm5vbmUgIWltcG9ydGFudDt0ZXh0LWFsaWduOmNlbnRlcjt0cmFuc2l0aW9uOmFsbCAwLjNzIGVhc2V9LnRiLWJ1dHRvbl9fbGluazpob3ZlciwudGItYnV0dG9uX19saW5rOmZvY3VzLC50Yi1idXR0b25fX2xpbms6dmlzaXRlZHtjb2xvcjppbmhlcml0fS50Yi1idXR0b25fX2xpbms6aG92ZXIgLnRiLWJ1dHRvbl9fY29udGVudCwudGItYnV0dG9uX19saW5rOmZvY3VzIC50Yi1idXR0b25fX2NvbnRlbnQsLnRiLWJ1dHRvbl9fbGluazp2aXNpdGVkIC50Yi1idXR0b25fX2NvbnRlbnR7Zm9udC1mYW1pbHk6aW5oZXJpdDtmb250LXN0eWxlOmluaGVyaXQ7Zm9udC13ZWlnaHQ6aW5oZXJpdDtsZXR0ZXItc3BhY2luZzppbmhlcml0O3RleHQtZGVjb3JhdGlvbjppbmhlcml0O3RleHQtc2hhZG93OmluaGVyaXQ7dGV4dC10cmFuc2Zvcm06aW5oZXJpdH0udGItYnV0dG9uX19jb250ZW50e3ZlcnRpY2FsLWFsaWduOm1pZGRsZTt0cmFuc2l0aW9uOmFsbCAwLjNzIGVhc2V9LnRiLWJ1dHRvbl9faWNvbnt0cmFuc2l0aW9uOmFsbCAwLjNzIGVhc2U7ZGlzcGxheTppbmxpbmUtYmxvY2s7dmVydGljYWwtYWxpZ246bWlkZGxlO2ZvbnQtc3R5bGU6bm9ybWFsICFpbXBvcnRhbnR9LnRiLWJ1dHRvbl9faWNvbjo6YmVmb3Jle2NvbnRlbnQ6YXR0cihkYXRhLWZvbnQtY29kZSk7Zm9udC13ZWlnaHQ6bm9ybWFsICFpbXBvcnRhbnR9LnRiLWJ1dHRvbl9fbGlua3tiYWNrZ3JvdW5kLWNvbG9yOiM0NDQ7Ym9yZGVyLXJhZGl1czowLjNlbTtmb250LXNpemU6MS4zZW07bWFyZ2luLWJvdHRvbTowLjc2ZW07cGFkZGluZzowLjU1ZW0gMS41ZW0gMC41NWVtfS53cC1ibG9jay10b29sc2V0LWJsb2Nrcy1ncmlkLWNvbHVtbi50Yi1ncmlkLWNvbHVtbltkYXRhLXRvb2xzZXQtYmxvY2tzLWdyaWQtY29sdW1uPSIzMDM0ZmJlODg2YzExMDU0ZTk1YjQ2YjA5ZDNlNDExMiJdIHsgZGlzcGxheTogZmxleDsgfSAudGItaW1hZ2Utc2xpZGVyLS1jYXJvdXNlbHtvcGFjaXR5OjA7ZGlyZWN0aW9uOmx0cn0udGItaW1hZ2Utc2xpZGVyIC5nbGlkZXtwb3NpdGlvbjpyZWxhdGl2ZX0udGItaW1hZ2Utc2xpZGVyIC5nbGlkZV9fc2xpZGV7aGVpZ2h0OmF1dG87cG9zaXRpb246cmVsYXRpdmU7bWFyZ2luLWxlZnQ6MH0udGItaW1hZ2Utc2xpZGVyIC5nbGlkZV9fc2xpZGUtLWNsb25le2N1cnNvcjpwb2ludGVyfS50Yi1pbWFnZS1zbGlkZXIgLmdsaWRlX19zbGlkZSBpbWd7d2lkdGg6MTAwJTtmbG9hdDpub25lICFpbXBvcnRhbnR9LnRiLWltYWdlLXNsaWRlciAuZ2xpZGVfX3ZpZXd7d2lkdGg6MTAwJTt0cmFuc2l0aW9uOm9wYWNpdHkgMzUwbXMgZWFzZS1pbi1vdXQ7cG9zaXRpb246cmVsYXRpdmV9LnRiLWltYWdlLXNsaWRlciAuZ2xpZGVfX3ZpZXcgaW1ney1vLW9iamVjdC1maXQ6Y29udGFpbjtvYmplY3QtZml0OmNvbnRhaW47d2lkdGg6MTAwJTtmbG9hdDpub25lICFpbXBvcnRhbnR9LnRiLWltYWdlLXNsaWRlciAuZ2xpZGVfX3ZpZXctLWZhZGUtb3V0e29wYWNpdHk6MH0udGItaW1hZ2Utc2xpZGVyIC5nbGlkZV9fdmlldy0tZmFkZS1pbntvcGFjaXR5OjF9LnRiLWltYWdlLXNsaWRlciAuZ2xpZGVfX2Fycm93e2JvcmRlcjpub25lO3Bvc2l0aW9uOmFic29sdXRlO3otaW5kZXg6MTA7dG9wOjUwJTtkaXNwbGF5OmlubGluZS1mbGV4O2p1c3RpZnktY29udGVudDpjZW50ZXI7YWxpZ24taXRlbXM6Y2VudGVyO3dpZHRoOjQwcHg7aGVpZ2h0OjQwcHg7dGV4dC1hbGlnbjpjZW50ZXI7cGFkZGluZzowO2N1cnNvcjpwb2ludGVyO3RyYW5zZm9ybTp0cmFuc2xhdGVZKC01MCUpO2JvcmRlci1yYWRpdXM6NTBweDt0cmFuc2l0aW9uOmFsbCAwLjJzIGxpbmVhcjtiYWNrZ3JvdW5kOnJnYmEoMjU1LDI1NSwyNTUsMC43KX0udGItaW1hZ2Utc2xpZGVyIC5nbGlkZV9fYXJyb3c6Zm9jdXN7b3V0bGluZTpub25lO2JveC1zaGFkb3c6MCAwIDVweCAjNjY2O2JhY2tncm91bmQ6cmdiYSgyNTUsMjU1LDI1NSwwLjcpO29wYWNpdHk6MX0udGItaW1hZ2Utc2xpZGVyIC5nbGlkZV9fYXJyb3c6aG92ZXJ7YmFja2dyb3VuZDpyZ2JhKDI1NSwyNTUsMjU1LDAuOSl9LnRiLWltYWdlLXNsaWRlciAuZ2xpZGVfX2Fycm93LS1sZWZ0e2xlZnQ6NXB4fS50Yi1pbWFnZS1zbGlkZXIgLmdsaWRlX19hcnJvdy0tbGVmdCBzdmd7bWFyZ2luLWxlZnQ6LTFweH0udGItaW1hZ2Utc2xpZGVyIC5nbGlkZV9fYXJyb3ctLWxlZnQgc3Bhbi50Yi1zbGlkZXItbGVmdC1hcnJvd3tkaXNwbGF5OmlubGluZS1ibG9jazt3aWR0aDoyNXB4O2hlaWdodDoyNXB4O2JhY2tncm91bmQtaW1hZ2U6dXJsKCJkYXRhOmltYWdlL3N2Zyt4bWwsJTNDc3ZnIHhtbG5zPSdodHRwOi8vd3d3LnczLm9yZy8yMDAwL3N2Zycgdmlld0JveD0nMCAwIDEyOSAxMjknIHdpZHRoPScyNScgaGVpZ2h0PScyNSclM0UlM0NnJTNFJTNDcGF0aCBkPSdtNzAsOTMuNWMwLjgsMC44IDEuOCwxLjIgMi45LDEuMiAxLDAgMi4xLTAuNCAyLjktMS4yIDEuNi0xLjYgMS42LTQuMiAwLTUuOGwtMjMuNS0yMy41IDIzLjUtMjMuNWMxLjYtMS42IDEuNi00LjIgMC01LjhzLTQuMi0xLjYtNS44LDBsLTI2LjQsMjYuNGMtMC44LDAuOC0xLjIsMS44LTEuMiwyLjlzMC40LDIuMSAxLjIsMi45bDI2LjQsMjYuNHonIGZpbGw9JyUyMzY2NicvJTNFJTNDL2clM0UlM0Mvc3ZnJTNFIil9LnRiLWltYWdlLXNsaWRlciAuZ2xpZGVfX2Fycm93LS1yaWdodHtyaWdodDo1cHh9LnRiLWltYWdlLXNsaWRlciAuZ2xpZGVfX2Fycm93LS1yaWdodCBzdmd7bWFyZ2luLXJpZ2h0Oi0xcHh9LnRiLWltYWdlLXNsaWRlciAuZ2xpZGVfX2Fycm93LS1yaWdodCBzcGFuLnRiLXNsaWRlci1yaWdodC1hcnJvd3tkaXNwbGF5OmlubGluZS1ibG9jazt3aWR0aDoyNXB4O2hlaWdodDoyNXB4O2JhY2tncm91bmQtaW1hZ2U6dXJsKCJkYXRhOmltYWdlL3N2Zyt4bWwsJTNDc3ZnIHhtbG5zPSdodHRwOi8vd3d3LnczLm9yZy8yMDAwL3N2Zycgdmlld0JveD0nMCAwIDEyOSAxMjknIHdpZHRoPScyNScgaGVpZ2h0PScyNSclM0UlM0NnJTNFJTNDcGF0aCBkPSdtNTEuMSw5My41YzAuOCwwLjggMS44LDEuMiAyLjksMS4yIDEsMCAyLjEtMC40IDIuOS0xLjJsMjYuNC0yNi40YzAuOC0wLjggMS4yLTEuOCAxLjItMi45IDAtMS4xLTAuNC0yLjEtMS4yLTIuOWwtMjYuNC0yNi40Yy0xLjYtMS42LTQuMi0xLjYtNS44LDAtMS42LDEuNi0xLjYsNC4yIDAsNS44bDIzLjUsMjMuNS0yMy41LDIzLjVjLTEuNiwxLjYtMS42LDQuMiAwLDUuOHonIGZpbGw9JyUyMzY2NicvJTNFJTNDL2clM0UlM0Mvc3ZnJTNFIil9LnRiLWltYWdlLXNsaWRlciAuZ2xpZGU6aG92ZXIgLmdsaWRlX19hcnJvdywudGItaW1hZ2Utc2xpZGVyIC5nbGlkZTpmb2N1cyAuZ2xpZGVfX2Fycm93e29wYWNpdHk6MX0udGItaW1hZ2Utc2xpZGVyLS1jcm9wIC5nbGlkZV9fc2xpZGUgaW1ney1vLW9iamVjdC1maXQ6Y292ZXI7b2JqZWN0LWZpdDpjb3ZlcjtoZWlnaHQ6MTAwJSAhaW1wb3J0YW50fS50Yi1pbWFnZS1zbGlkZXIgLmdsaWRlX19zbGlkZXN7bGlzdC1zdHlsZS10eXBlOm5vbmU7cGFkZGluZy1sZWZ0OjA7bWFyZ2luLWxlZnQ6YXV0b30udGItaW1hZ2Utc2xpZGVyX19jYXB0aW9ue3Bvc2l0aW9uOmFic29sdXRlO2JvdHRvbTowO3dpZHRoOjEwMCU7YmFja2dyb3VuZDpyZ2JhKDI1NSwyNTUsMjU1LDAuNik7dGV4dC1hbGlnbjpjZW50ZXI7Y29sb3I6IzMzM30udGItaW1hZ2Utc2xpZGVyX19jYXB0aW9uIDplbXB0eXtiYWNrZ3JvdW5kOnRyYW5zcGFyZW50ICFpbXBvcnRhbnQ7bWFyZ2luOjA7cGFkZGluZzowfS50Yi1pbWFnZS1zbGlkZXJfX2NhcHRpb24gZmlnY2FwdGlvbntwYWRkaW5nOjVweCAycHg7bWFyZ2luLXRvcDo1cHh9IH0g

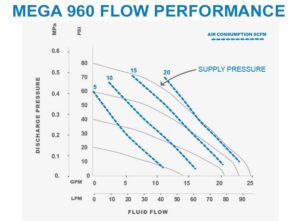

Max Flow: 95 LPM (25 GPM)

Max Temperature: 212 °F (100 °C)

Max Pressure: 80 PSIG (0.55 MPa)

Materials: PTFE/PFA fluid path

All wetted seals are PTFE

Certifications: CE

Applications: Semiconductor/Electronics

LED/Flat Panel

Chemical Processing

Delivery

Aerospace

The Mega 960 is ideal for high-flow recirculation or delivery applications. It features a non-stalling shuttle valve to operate reliably under high pressure and closed discharge valve conditions. This pump’s flow path is constructed entirely of PFA and PTFE to ensure the utmost high-purity pumping and chemical compatibility. The non-metallic air chamber components make this pump suitable for aggressive acid vapor environments. This is the go-to standard for high-flow chemical applications where non-stop performance is essential.

- Reliable Operation In Various Applications Because Of Patented Non-Stall Air Logic Design

- Safe, Pneumatic Operation With Clean, Dry Air Or Nitrogen

- High Suction Capability Due To Patented Floating PTFE O-Ring Check Valve

- Non-Penetrated, Double Layer PTFE Diaphragm

- Immediate Response To System Backpressures (D-Style Control Only)

- User Serviceable

- Clean Room Assembled, Tested, And Packaged

CONTROL STYLES

- 960E For User Defined

- 960D For Distribution And Deadhead Capability

FLUID PORT CONNECTIONS

- ¾” Flare Tube Adapter

- 1″ Flare Tube Adapter

- ¾” PFA Tube Stubout

- 1″ PFA Pipe

- ¾” NPT

- 1″ NPT

- No Adapter

SURGE SUPPRESSOR

- SS85

- SS95

OTHER OPTIONS

- Viton® Or FFKM Air-Side Seals

- Cycle Probe (960D Only)

- Remote Exhaust

- Leak Probe

- Magnetic Shuttle

DATASHEET

MANUAL

CERTIFICATION

CAD FILES/DRAWINGS

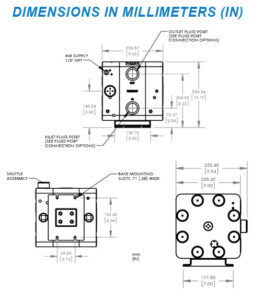

Mega 960 – DRAWING Mega 960D – MODEL Mega 960E – MODEL

BLOGS